Simply put, we tell good stories well – on screen, in print, on line, and in person.

Write good words.

We bring to life the tales that matter through film, copy, editorial and events.

We’re writers. We find the hook, the line, the story, and put them into words that resonate.

Film

From ideation and development to writing films, documentaries, interviews, brand content and series, we have a proven track record in delivering impactful, insightful storytelling.

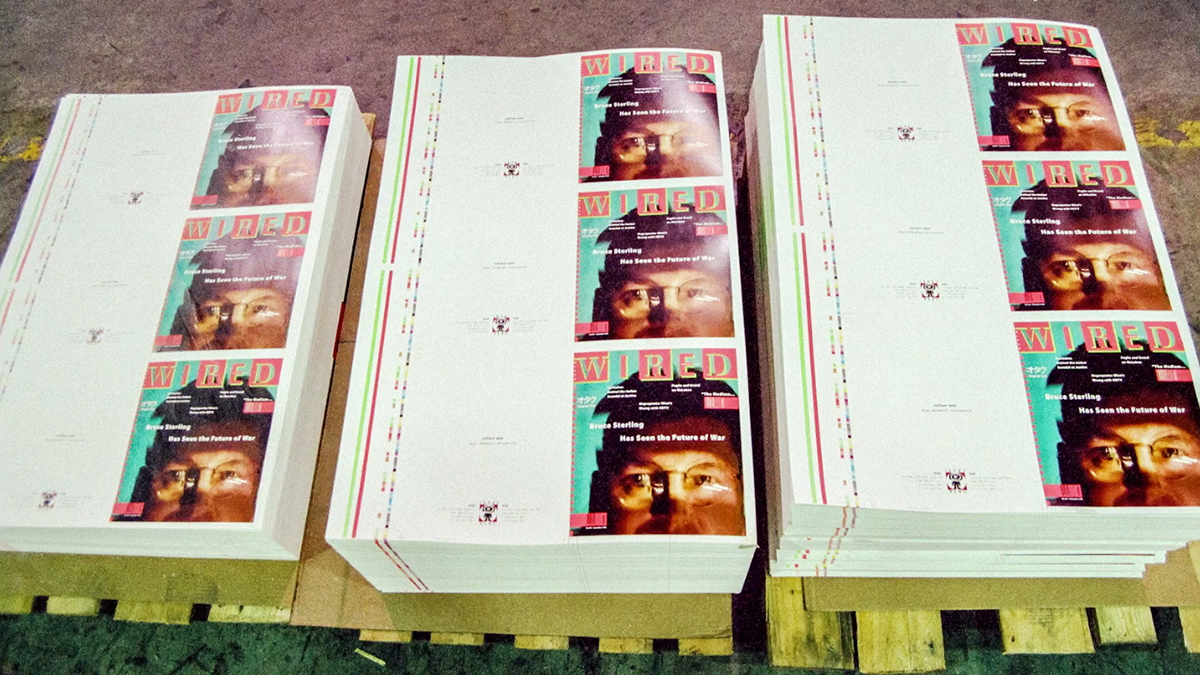

Copy

Whether teasing out the creative edge of a brand tale or translating complex concepts into compelling content, at the heart of everything is the story, and the telling of it.

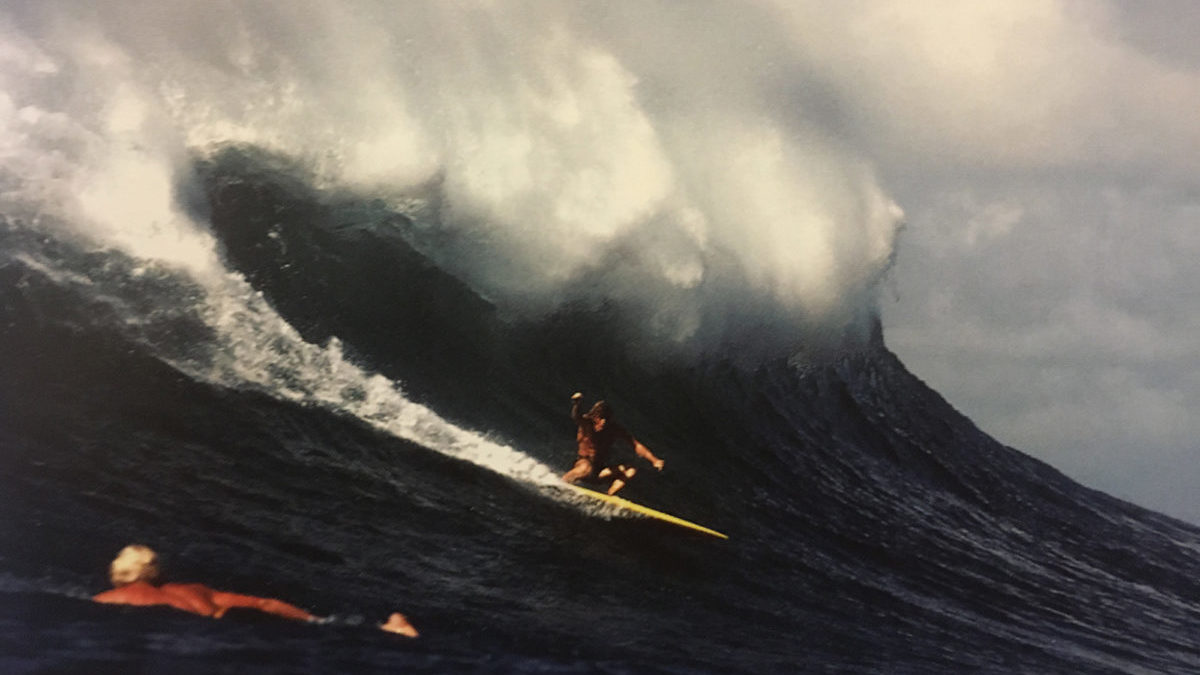

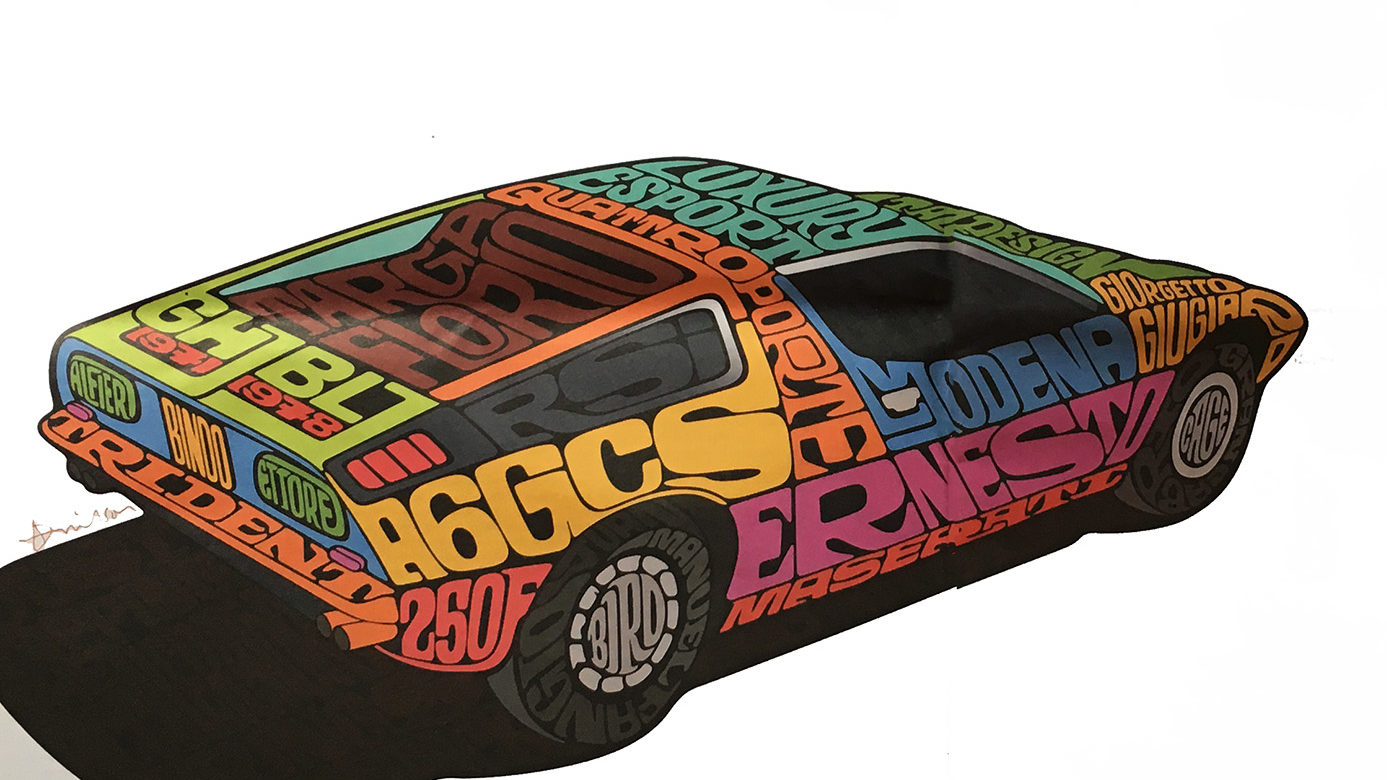

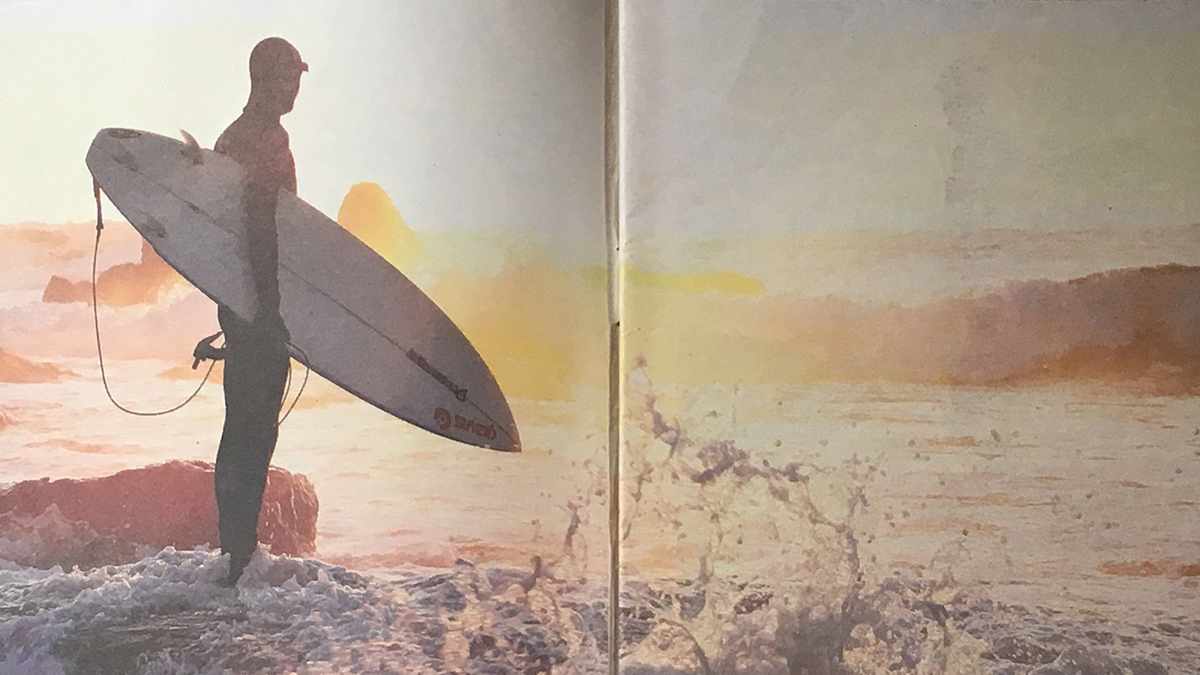

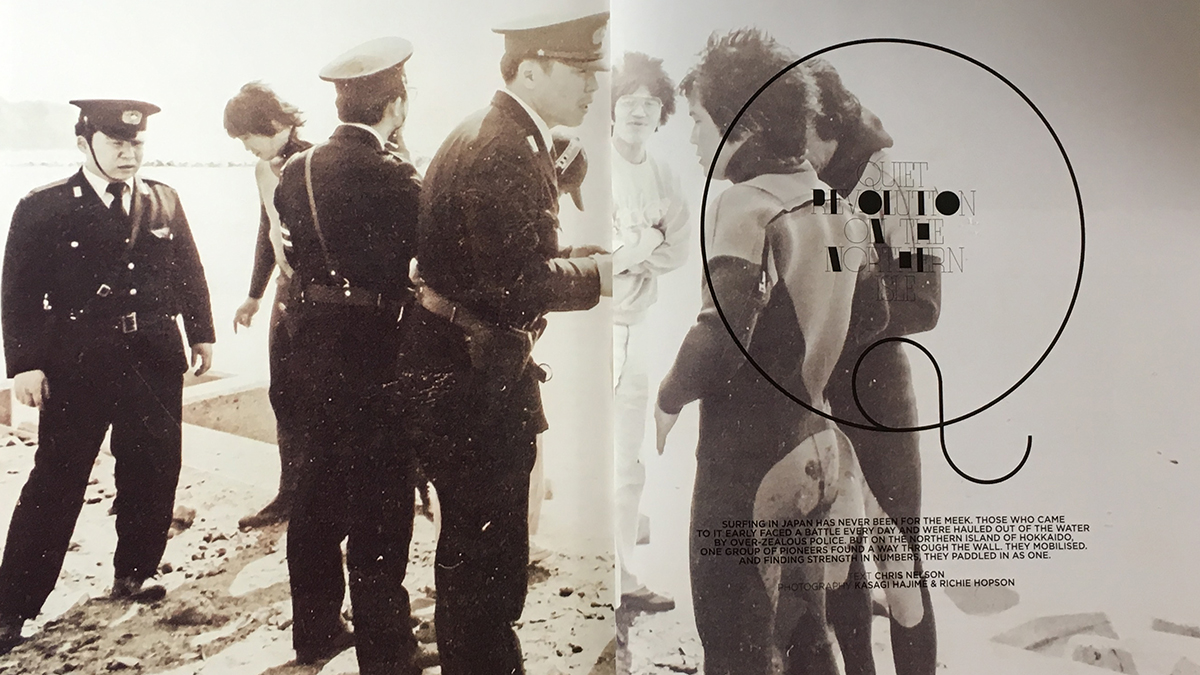

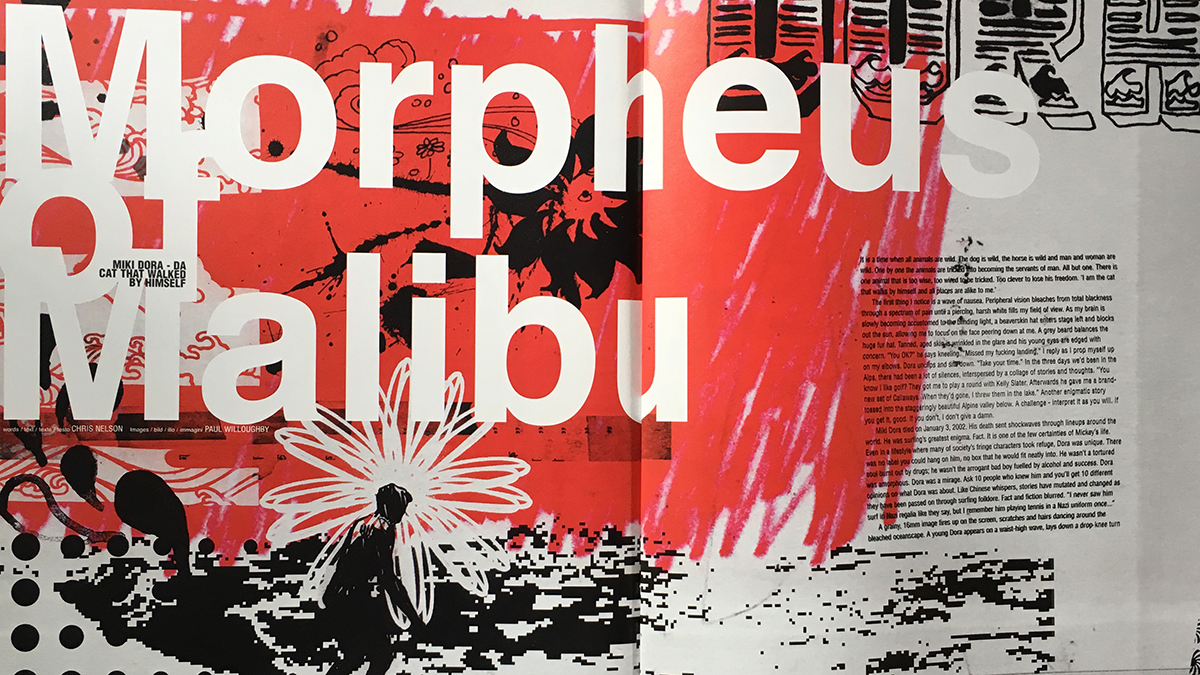

We write for the national press and lifestyle media about surf, travel, cars and culture. We’ve also written ten best-selling books charting the journeys and unearthing the tales that count.

Events

We work with leading brands and creatives to produce international festivals, to curate compelling events and authentic activations that inspire community and always deliver.

We’ve worked with some exceptional brands, partners & businesses.

Good stories, good people.

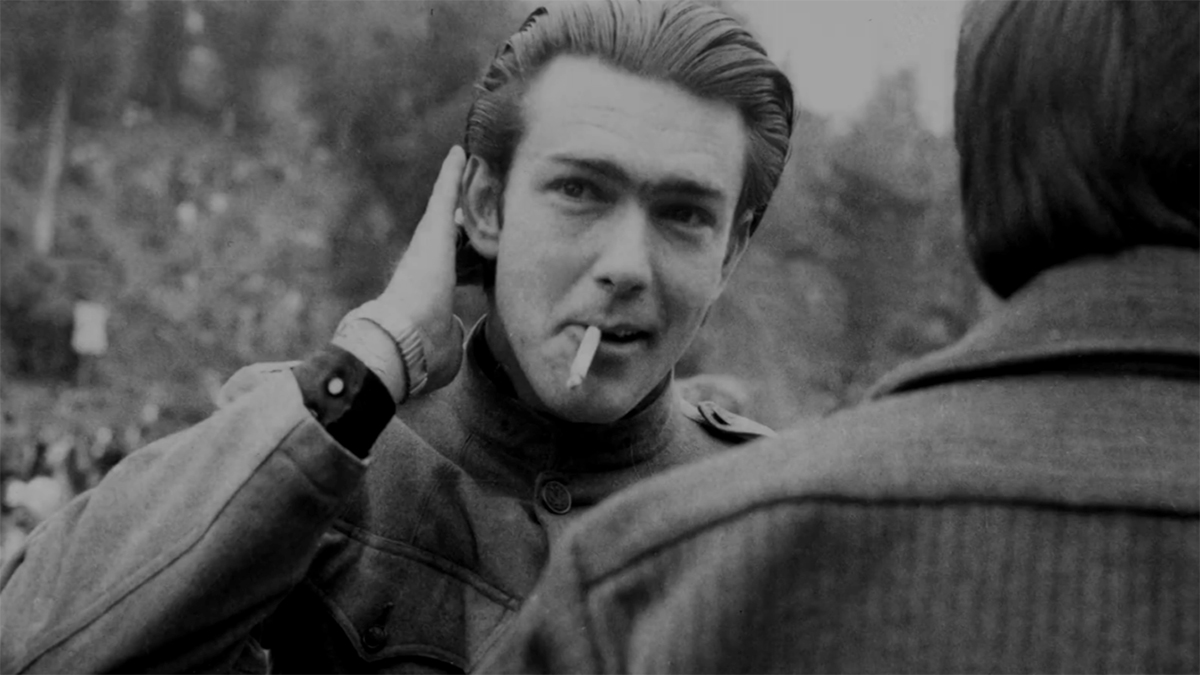

Featured Work

People, places, pioneers, brands, bands, icons and happenings.